ZNC EDM Die Sinker ZNC250/320

ZNC EDM Die Sinker ZNC250/320 is small size single axis CNC control spark machine. Mainly used for processing molds and parts with complex shaped holes and cavities, various conductive materials, such as cemented carbide and quenched steel, etc.

| ZNC250 Travel | 250/200/200 |

|---|---|

| ZNC320 Travel | 300/200/200 |

| Max Electrode Weight | 25kg |

Details About ZNC EDM Die Sinker ZNC250/320

Technical Parameters:

| Model | ZNC250 | ZNC320 | |

|---|---|---|---|

| Worktable dimension (mm) | 450*280 | 500*300 | |

| Axis travel | X Axis (mm) | 250 | 300 |

| Y Axis (mm) | 200 | 200 | |

| Z Axis (mm) | 200 | 200 | |

| Processing liquid tank internal size (mm) | 790*495*280 | 835*550*320 | |

| Max electrode weight (kg) | 25 | ||

| Max load (kg) | 200 | 300 | |

| Distance from electrode plate to worktable | Min (mm) | 350 | 350 |

| Max (mm) | 550 | 560 | |

| Oil tank capacity (L) | 400 | ||

| Power supply (V) | 380V, 50HZ (Can be customized) | ||

| Weight (kg) | 1050 | 1200 | |

| Dimension (mm) | Host Machine Overall Dimension (mm) | 1320*1100*2050 | 1320*1150*2060 |

PS: All the working area and specifications can be customized according to your requests.

Machine Features:

- The machine is designed by special CAD software, in good structure and high precision, and has reasonable back-oil groove to insure clean and beautiful machine.

- Principal axis adopt high precision DC servomotor to insure high quality and long machine life.

- Principal axis adopt precision screw (made in Taiwan), lubrication adopt spindle box lubricate, without noise, without high temperature, less friction and high precision.

- X,Y axis adopt high precision repressed bearing working in high precision ball screw,with good rigidity and portability operation.

- Oil pump imported from Italy with big flowing and low error.

- Can arbitrarily choose the methods of removing scrap iron, sweeping oil or sucking oil, also choose process that the workpiece is not submerged in oil.

- It suits to process cavity, hole and special shape parts in copper, plumbago, steel.

Electric Cabinet Features:

- LCD or numerical tube operation interface.

- Adopting fuzzy control theory and carbon deposition auto checking, it can have auto clapper and residue extraction when is unstable discharge.

- Multilevel loss can be transferred,it can satisfy various areas and mould processing requirements.

- With special mirror processing circuit.

- Z axis with max 9 level edit and processing. From rough processing to fine processing can be finished in one time.

- Intelligent specialist data system, easy for the beginner to use.

- Early warning of multiple dangers, protection, and reduction of unnecessary damage due to the mistaken operation.

- There are some safe devices in circuit.

Electric Control Cabinet

| Model | 40AMP | 80AMP | 100AMP |

|---|---|---|---|

| Max processing current (A) | 35 | 75 | 95 |

| Max processing speed (mm³/Min) | 200 | 500 | 600 |

| Min electrode consumption | ≤0.2% | ≤0.2% | ≤0.2% |

| Best surface roughness (μm) | Ra<0.8 | Ra<0.8 | Ra<0.8 |

| Total input power (kw) | 3.5 | 7.5 | 12 |

| Weight (kg) | 200 | 200 | 220 |

| Dimension (mm) | 800*540*1700 | 800*540*1700 | 800*540*2000 |

Share ZNC EDM Die Sinker ZNC250/320 With Others

Facebook

LinkedIn

Twitter

Email

Related products

-

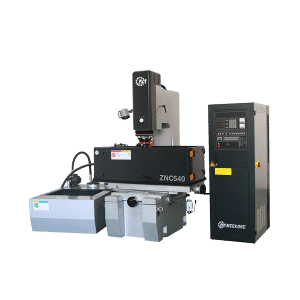

EDM Die Sinking Machine ZNC540/760

Select options This product has multiple variants. The options may be chosen on the product page -

Single Axis CNC EDM Die Sinker ZNC325/435

Select options This product has multiple variants. The options may be chosen on the product page