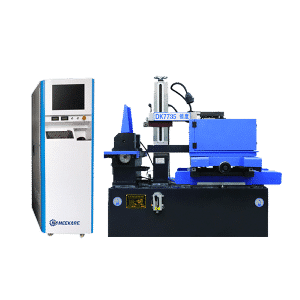

Fast Speed EDM Wire Cut Machine DK Series

Fast Speed EDM Wire Cut Machine DK Series is widely used in fields of mold, bulk production, electronic equipment, precision machinery, medical equipment, auto parts, aerospace and military industries, etc.

| Max Cutting Speed (mm²/Min) | 200 |

|---|---|

| Machining Roughness | Ra≤2.5 |

| Machining accuracy (mm) | 0.015 |

| Moly Wire Dia. (mm) | 0.18 |

Details About Fast Speed EDM Wire Cut Machine DK Series

Technical Parameters:

| Model | DK7745 | DK7745F | DK7750 | DK7750F |

| Worktable Dimension (mm) | 840*600 | 950*600 | 1000*670 | 1150*670 |

| Worktable Travel (mm) | 450*550 | 450*630 | 500*630 | 500*800 |

| Max Cutting Thickness (mm) | 400-600 | 400-600 | 500-800 | 500-800 |

| Max Cutting Taper (°) | ±3°/±15°/80mm | ±3°/±15°/±30°/±45°/80mm | ||

| Max Cutting Speed (mm²/Min) | ≥120 (High speed controller ≥200) | |||

| Machining Roughness (Ra, μm) | Ra≤2.5 (Middle speed. Ra≤1.0) | |||

| Molybdenum Wire Diameter (mm) | 0.18 | |||

| Machining Accuracy | As per GB7926-2005 | |||

| Power Supply | AC 3PH, 380V, 50HZ | |||

| Power Consumption (KVA) | <1.0#colspan# | |||

| Max Load (kg) | 400 | 450 | 800 | 800 |

| Host Machine Net Weight (kg) | 1250 | 1350 | 2150 | 2350 |

| Host Machine Overall Dimension (mm) | 1700*1430*1700 | 1700*1540*1700 | 2000*1750*2000 | 2000*1900*2000 |

As our company continuously developing and improving our products, the specification parameters might change without notice.

Using Scope:

- Mainly suitable for machining kinds of stamping die, mold powder metallurgy, mosaic cavity mold, drawing die, corrugated board molding.

- Can be used for machining tiny holes, shaped groove, narrow, standard defects and complex-shaped workpiece.

- Can be used for machining model forming parts, tool cam and special cam gear.

- Can be used for machining high hardness materials, cutting into thin slices, cutting precious metal materials.

Features:

- Stable structure: Use high quality casting materials, resin sand process, enhanced internal stiffeners, after 2nd tempering and natural aging, which reduces casting distortion. Guide rail after bearing steel forging through heat treatment, to reach the standard hardness, and extend the using life.

- High precision process: All parts are machined by CNC Machining Center and precision grinding machine, to ensure machining accuracy and assembling accuracy, and ensure our products’ quality.

- Practical technology: Wire transport cylinder’s surface is after hardening treatment, to increase its wear resistance and make it durable.

Optional Configuration:

- Electronic scale: High precision optical electronic scale digital display, can realize X, Y-axis real-time location tracking.

- Frequency electrical appliances: Machine’s electrical appliance can choose frequency control.

- Wire rack lifting: Wire rack is optional, can choose electric lifting function.

High speed Controller

● Industrial PC

● Full cover protection

● Good heat dissipation

● Multi-cut function

● Cutting parameter system

● Center find function

● AutoCAD software

● AutoCUT system

● Parameter fast setting

● Fast cutting speed

● Optional: High accuracy full closed loop technology

Share Fast Speed EDM Wire Cut Machine DK Series With Others

Facebook

LinkedIn

Twitter

Email

Related products

-

Wire EDM Machine Fast Speed DK7763/63F

Select options This product has multiple variants. The options may be chosen on the product page -

CNC Wire EDM Machine DK7750/50F

Select options This product has multiple variants. The options may be chosen on the product page -

CNC EDM Wire Cut Machine DK7735/40

Select options This product has multiple variants. The options may be chosen on the product page -

Wire Cut EDM Machine Small Model

Select options This product has multiple variants. The options may be chosen on the product page