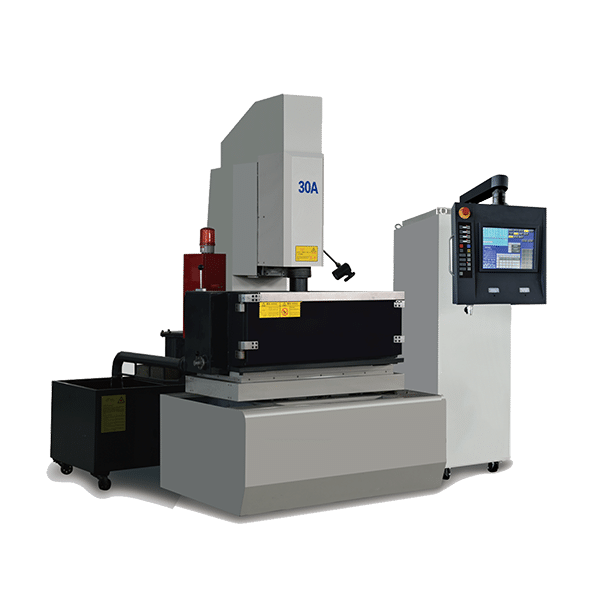

High Precision CNC Mirror EDM Die Sinker CNC-30A/35A

High Precision CNC Mirror EDM Die Sinker CNC-30A/35A are mirror spark machine, with high accuracy. Mainly used in the precision machining of complex mold cavities, especially complex curved surfaces that are not convenient for polishing.

| Machining accuracy | 0.005 at any 100mm |

|---|---|

| Repeat machining accuracy | 0.002mm |

| Best surface roughness | Ra≤0.08μm |

| Max processing current | 40A |

| Axis control | Three-axis three linkage |

Details About High Precision CNC Mirror EDM Die Sinker CNC-30A/35A

Technical Parameters:

| Model | Unit | CNC-30A | CNC-35A | |

|---|---|---|---|---|

| Worktable size | mm | 600*400 | 600*400 | |

| X/Y/Z travel | mm | 300/210/270 | 350/250/270 | |

| Working tank internal size (L*W*H) | mm | 950*620*360 | 950*620*360 | |

| Max electrode weight | kg | 25 | 50 | |

| Max workpiece weight | kg | 400 | 400 | |

| Distance from electrode installation plate to worktable | Min | mm | 295 | 250 |

| Max | mm | 565 | 550 | |

| Total input power | KVA | 9 | ||

| Power supply | 380V, 50HZ (Can be customized) | |||

| Max processing current (A) | A | 40 | ||

| Axis control number | Three-axis three linkage | |||

| Machining accuracy | mm | 0.005 at any 100mm | ||

| Repeat machining accuracy | mm | 0.002 | ||

| Best surface roughness (μm) | μm | Ra≤0.08 | ||

| Weight | kg | 2000 | 2200 | |

Functions:

- LCD touch screen display and input.

- X/Y/Z three-axis three linkage function. Four-axis four linkage (optional).

- Super finishing PIKA circuit – mirror processing function.

- Expert processing technology database:

Combination of electrode and workpiece materials for automatic processing and manual processing: copper/steel, graphite 1/steel, graphite 2/steel, copper/aluminum alloy, graphite 1/aluminum alloy, graphite 2/aluminum alloy, silver tungsten, copper tungsten /steel, silver tungsten, copper tungsten/hard alloy, copper/zinc alloy, graphite/zinc alloy, copper/copper alloy.

- AUTO processing function

Input electrode and workpiece material, processing area, electrode scaling, final processing surface roughness and other processing information, the system automatically calculates the processing parameters according to the expert processing technology database, and automatically completes the whole process from roughing to finishing.

- Automatic positioning function

It has end face positioning, angular positioning, column center positioning, hole center positioning, arbitrary three-point circle center positioning, and discharge position alignment positioning function. At the same time, the automatic positioning function can be used to perform online measurement and online correction on the processed workpiece.

- Automatic arc-clearing circuit

During the process of electrical discharge machining, the condition of the machining gap is monitored in real time, and when a slight short circuit or arcing occurs, the alarm is applied and the arc cleaning process is performed in time.

- Liquid level control, liquid temperature control, automatic fire extinguishing device.

- Power-off reset function.

The machine can memorize the coordinate values of the current coordinate system, and in case of unexpected situations such as sudden power failure, the set coordinate points can be found after restarting.

Share High Precision CNC Mirror EDM Die Sinker CNC-30A/35A With Others

Related products

-

Mirror Spark Machine EDM Die Sinker CNC-40E/70E

Select options This product has multiple variants. The options may be chosen on the product page -

CNC Spark Machine EDM Die Sinker CNC-40B/45B

Select options This product has multiple variants. The options may be chosen on the product page -

Three Axis CNC EDM Die Sinker CNC-30B/35B

Select options This product has multiple variants. The options may be chosen on the product page -

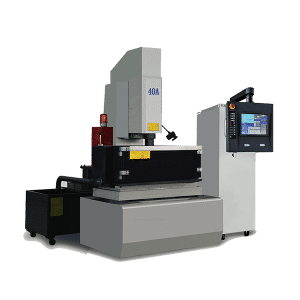

CNC EDM Die Sinker CNC-40A/45A

Select options This product has multiple variants. The options may be chosen on the product page