Handling of the deviation of the threaded hole during the WEDM processing

If the position of the threading hole is found to be offset, there is a deviation from the coordinate position in the program. The method is to move the XY axis and thread the molybdenum wire into the threading hole to ensure that there is no short circuit (the voltmeter indicates 5V). Without terminating the current processing program, use “manual processing” to the threading point of the current hole of the program at the coordinates, close the “Manual processing” window, move the X or Y axis of the machine with a movement greater than 0.001mm, and then click the back to pause point in the EDM processing interface, and press the green processing button on the manual control box to start processing.

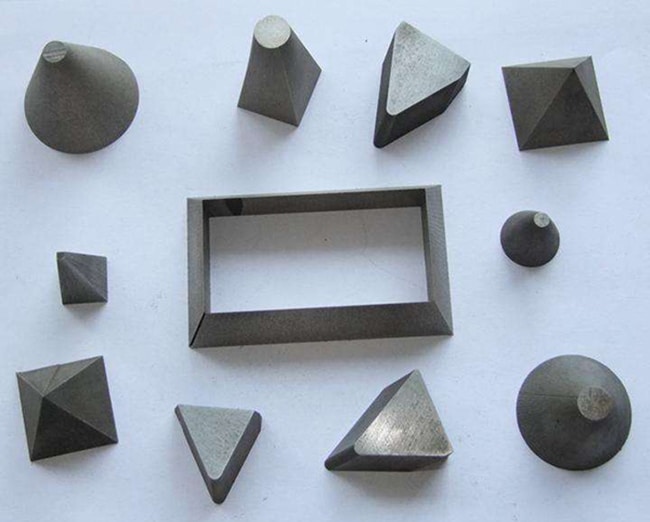

The change of the guide wheel tangent point affects the processing size, resulting in trapezoidal error. In order to reduce this error, the graph can be rotated 45°, and linkage the X and Y axes, then this error can be greatly reduced. Another method is to add a transition circle at the corner when the workpiece allows. Due to the existence of a small transition circle, an over-cut will be formed, and an alarm of “over-cut or arc radius too large” appears during cutting, can change small the “Workpiece thickness” this taper cutting parameter manually. Some taper parts’ one end is found to be cut after processing – When taper programming, the “retract length” should be changed to be greater than or equal to the length of the feed line, one end is found to be cut-the “retract length” should be changed to be greater than or equal to the length of the feed line during taper programming.